Soldering and Prototyping

Soldering is the quickest, easiest and many times the only way to make connections. It’s also the best way to electrically connect to conductors together.

I get a lot of questions regarding soldering. This page is meant to serve as a starting point to building up some decent soldering skills. Now a few things to get out of the way. First off, soldering is a craft. By craft, I mean that the first time you solder something, it will probably be ugly, that’s ok. No one including myself was born knowing how to make perfect solder joints. It takes some practice and patience.

Rule #1 – Good looking quality solder joints are a function of skill, not the cost of your soldering iron. I can make a $5 soldering work just fine.

Rule #2 – Keep the tip of the soldering iron clean and regularly tinned. Ease of soldering is about transferring heat from the soldering iron to the 2 conductors you want to connect, i.e. solder together. The only way this will happen is to regularly (maybe even after every solder joint, wipe the tip on a wet sponge and add some fresh solder to the iron (called tinning).

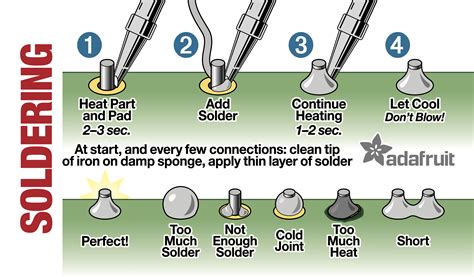

Rule #3 – Heat up both conductors at the same time and feed the solder into the conductors you are trying to join, not the iron. For a good example see the first image below

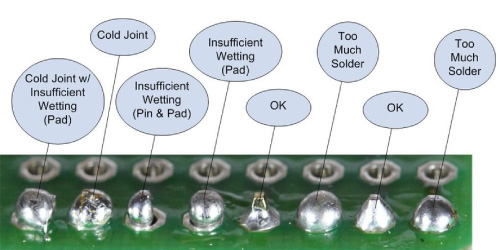

If you are wondering if a solder joint is good or not, the next image is a great example of good vs bad joints and what is probably the issue if you aren’t getting good results.

Here is a great image showing the steps to get a good result.

Prototyping

When constructing a circuit, whether it’s an embedded system, analog circuit, digital circuit or some combination of all of the above, we have a few different techniques to prototype. We can breadboard, point-point solder using some perfboard, or create a PCB – Printed Circuit Board and solder our components to a professionally made by us circuit board.

Breadboarding

Breadboarding is great for small circuits and as a proof of concept of simpler circuit elements. Breadboarding is less permanent and prone to falling apart over time. I want to create some videos for this section, but for right now, I have a lot of breadboarding examples in the 211 and 311 lecture videos toward the end discussing labs. For right now use those resources until I get some time to add to this section.

Point-To-Point Soldered Prototype

Most of the time when I want a more permanent circuit that I don’t want to take the time or money to have a professionally made PCB – – Printed Circuit Board, I’ll solder the components directly to a piece of Perf/Prototype Board. Here’s a video I put together detailing how I constructed a simple current reference standard that I wanted for the purpose of comparing the current measuring abilities of my multimeter’s.

Prototyping Perfboard Current Standard 09 24 20

Manhattan Style Point-To-Point

Printed Circuit Board Creation